Do you need an automated pipetting solution to cover a single, sell-defined application or are you looking for a versatile tool to cover multiple applications?

- Applications

-

Products

-

Liquid Handling

- firefly Accelerate genomic research with innovative all-in-one, compact liquid handling

- mosquito Nanolitre liquid handling technology performs ‘traditional’ tasks at a fraction of the volume, and higher speeds

- dragonfly Delivers accurate and repeatable nanolitre to milliliter dispensing

- apricot Automated liquid handling instrumentation for convenient general use across your entire team

- Sample Preparation

-

Sample Management

- comPOUND A scalable, reliable, and secure compound management solution

- BioMicroLab Easy-to-use sample management automation instruments

- arktic Robust biospecimen storage and management down to -80°C

- lab2lab Novel sample and data transfer network system

- comPACT Reliable and efficient -20°C storage and retrieval has never been more accessible

-

Liquid Handling

-

About

- Company With a focus on liquid handling, sample preparation and sample management, our expert teams create state-of-the-art solutions that scientists and researchers can trust Culture We have one overarching mission: to work together to accelerate life science research. Through our innovative solutions and state-of-the-art tools, we believe we can make a real difference to human health Partners Collaboration is key in our mission to make a real difference to human health. Partnering with application leaders globally, we co-create to solve new challenges across the life sciences. Innovation From the initial prototype through to manufacturing, installation and beyond, we bring a problem-solving mindset and technical expertise to drive innovation

-

Executive Leadership

Through strategic guidance, visionary thinking, and a relentless pursuit of excellence, our senior executives steer SPT Labtech towards achieving its mission of making a real difference to human health through solving advanced laboratory challenges.

Learn more

Through strategic guidance, visionary thinking, and a relentless pursuit of excellence, our senior executives steer SPT Labtech towards achieving its mission of making a real difference to human health through solving advanced laboratory challenges.

Learn more

-

View all

Board of Directors

Board of Directors

Our Board of Directors are committed to driving the long-term success and sustainability of SPT Labtech, providing expert guidance and oversight to execute the company’s ambitious commercial strategy.

Learn more

Our Board of Directors are committed to driving the long-term success and sustainability of SPT Labtech, providing expert guidance and oversight to execute the company’s ambitious commercial strategy.

Learn more

-

Knowledge Base

- Resources Our wide range of insightful resources include videos, whitepapers, eBooks, application notes and more Events & Webinars Meet the SPT team at events all over the globe and virtually via our webinars Podcast We chat with innovators and leaders from across the community to gain their unique insights. News Latest news from SPT Labtech globally Blog Our latest blog posts feature trends in research, innovative techniques and new technology

-

25 February, 2026

SPT Labtech to collaborate with Illumina to develop automated platform supporting genomics in decentralized healthcare settings

Continue reading

SPT Labtech to collaborate with Illumina to develop automated platform supporting genomics in decentralized healthcare settings

Continue reading

-

09 February, 2026

SPT Labtech and BellBrook Labs Introduce High-Throughput Screening Platform for Cancer Research

Continue reading

SPT Labtech and BellBrook Labs Introduce High-Throughput Screening Platform for Cancer Research

Continue reading

-

14 January, 2026

.jpg?length=320&name=Twist%20x%20SPT%20Labtech%20Press%20Release%20(1200%20x%20800%20px).jpg) SPT Labtech enables automated Twist Bioscience NGS library preparation workflows on firefly platform

Continue reading

SPT Labtech enables automated Twist Bioscience NGS library preparation workflows on firefly platform

Continue reading

10

- Careers

- Home

- Automated Pipetting

Automated pipetting - the complete guide

Laboratories across the biotech and pharmaceutical industries are increasingly automating their liquid handling and dispensing capabilities with versatile, scalable, and affordable solutions that cater to a range of applications.

Choose the right automated solution for your laboratory

1. What is automated pipetting?

Transferring a measured volume of liquid from one container to another was traditionally performed with manual pipettes. The main benefits of automated pipetting systems over manual pipetting are clear: increased throughput, greater accuracy, and better workflows delivering substantial time and cost savings.

- Manual pipetting activities can take up more than 80% of the workday for certain laboratory employees. And so it's no surprise that many labs are seeking to increase their throughput with faster, automated liquid handling processes.

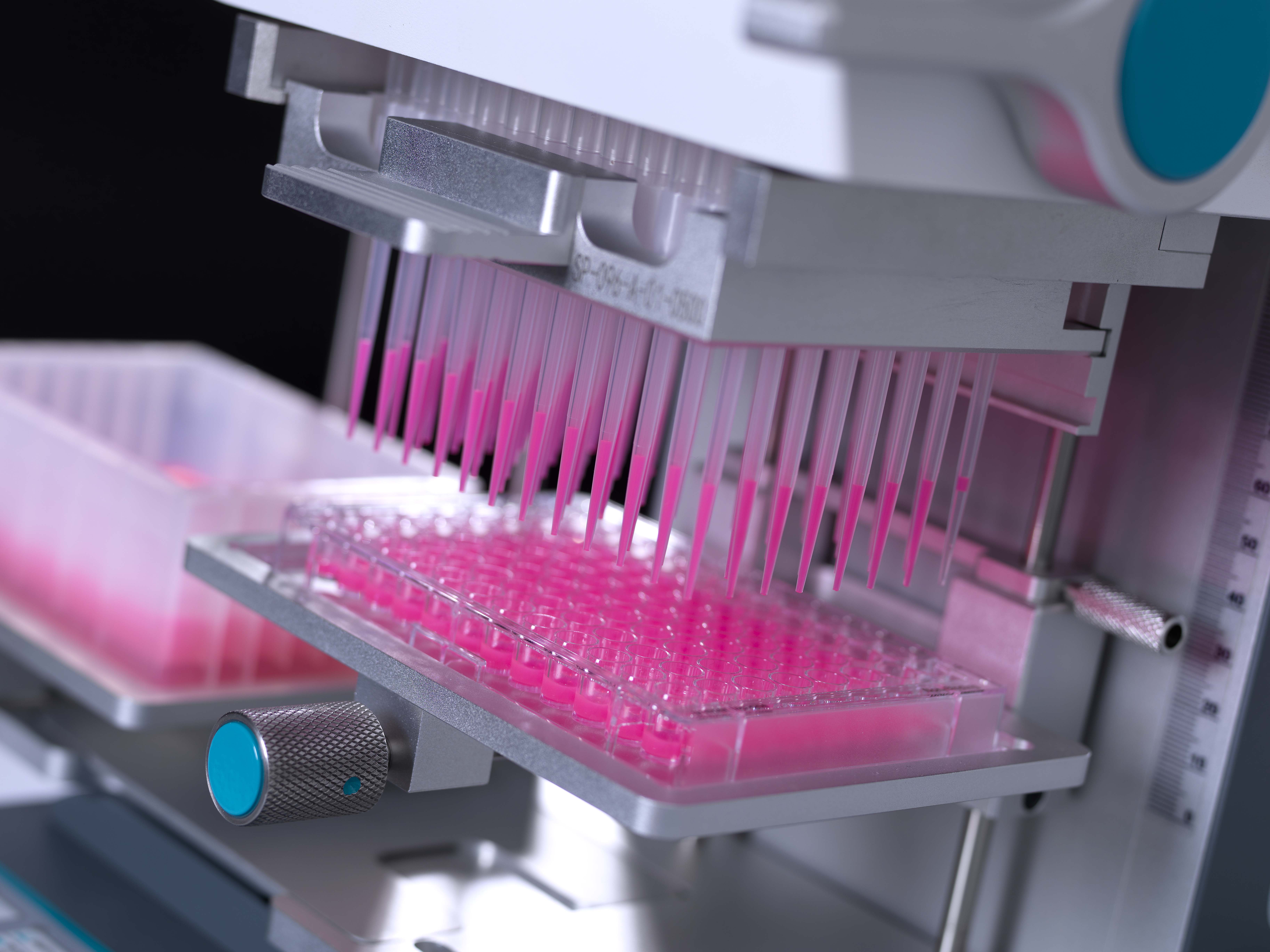

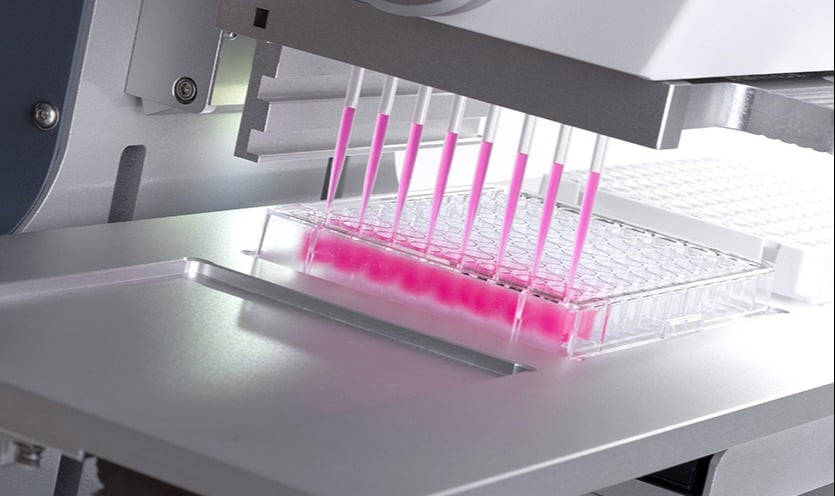

- Automated pipetting systems fall under the category of liquid handling instruments, which are typically used for copying, aliquoting, pooling and mixing and the serial dilution of liquids. Compared to manual pipetting, automated liquid handling systems are designed to speed up the process of pipetting and dispensing liquid, while at the same time significantly increasing the accuracy of workflows for different liquid types and volume ranges.

2. Manual vs semi-automated vs automated pipetting systems

Single or multi-channel handheld electronic pipettors are first step towards an automated workflow. Automated pipetting systems range from small benchtop liquid handling units and dedicated low-volume liquid handlers to complete automated pipetting workstations. Even more fully automated solutions include integrated work cells, where multiple liquid handlers are often used alongside dispensers, readers, plate hotels, and robotic arms to move the plates around.

Liquid handling automation doesn't have to be complex. While fully integrated work cells are superb, automated pipetting and dispensing platforms, which can offer full walk-away capability, they come at a high cost and are out of reach for most laboratories. But that doesn't mean that all the benefits of automation, from increased throughput, reliable standardization, and improved data quality can't be achieved with a simple benchtop unit.

Manual pipettors work well for simple applications with a low level of throughput. Typically they'll involve a low number of samples, and some degree of variability between the pipetting techniques of different human operators has to be taken into account. Manual pipetting isn't suitable for high-throughput applications because of the time and costs involved as well as RSI risks to laboratory staff.

Semi-automated tools control the volume for greater accuracy and go some way to increasing throughput and reproducibility. Using a semi-automated pipetting instrument usually means that certain liquid handling steps are automated, such as aspiration and dispensing, but user intervention is still required, e.g. to move plates between steps or exchange tips, depending on the semi-automated system. Automated pipetting (semi- or full) minimizes interaction with the user and may be preferred when working with hazardous substances.

Automated systems can be used to provide higher throughput without user intervention. They allow you to automate individual protocol steps or achieve full walk-away automation of complex protocols. Greater automation can be achieved through inbuilt functionality, e.g. plate grippers to move plates around a deck, or via integration with robotic devices such a robotic arms and plate hotels. But automated or robotic liquid handlers aren't limited to complex methods or bespoke and fully automated workflows. Increasingly, labs are making use of and benefiting from affordable and versatile benchtop solutions for wide variety of applications.

Which is the best option for your lab?

*Scroll to view more information

Manual pipetting

Semi-automated pipetting

Automated pipetting

Number of samples

Small (< 10)

Medium (10 -100)

High ( > 100)

Level of throughput required

Up to 10 samples per hour

Up to 100 samples per hour

More than 100 samples per hour

Reproducibility

Low

High

High

Dead volumes

Low

None, or low

High

Possible exposure to hazardous liquids

Yes

Yes

No

RSI risk

Yes

Potentially

No

Labor costs

High

Moderate

Low

3. Positive displacement pipette vs air displacement pipette vs acoustic technology

Automated liquid transfer systems cater to different volume ranges and liquid types.

Do you need to work with a single microplate format, large dynamic volumes or cells that require sterile conditions after automated dispensing?

Volume and liquid type considerations are the chief factors that determine which displacement technology is most appropriate for your laboratory's workflows.

Air displacement pipetting

Air displacement pipetting relies on an air cushion between the pipette piston and liquid. Movement of the piston inside the pipette creates a positive or negative pressure that moves liquid in or out of the pipette tip. Air displacement pipetting is highly accurate for standard pipetting applications above 2 μL and liquids that don't have extreme viscosities. It works with a simpler tip and more economical design compared to the positive displacement pipette.

Positive displacement pipetting

Positive displacement pipetting and dispensing is based on a piston that comes into direct contact with the liquid. Mechanical movement of the piston inside a pipette tip or dispense syringe enables highly accurate and repeatable delivery of liquid volumes.

Positive displacement technologies are liquid-class agnostic, which means they handle a diverse range of liquid viscosities. Positive displacement pipettes have a more complex tip design, to offer highly accurate pipetting in the sub-microliter volume range, regardless of liquid type, e.g. glycerol or ethanol.

Acoustic technology

Acoustic liquid handlers, as the name suggests, use sound to transfer precision droplets of liquid to a target well. Acoustic technology allows for the transfer of tiny droplets (of less than 1 μL) and, by not using plastic tips, acoustic devices significantly reduce the amount of waste produced by a lab. However, they are unable to transfer ‘intra-plate’ or handle higher transfer volume as they rely on an inverted destination plate positioned directly over the source plate which can be limiting for some applications. Additionally, in-well mixing cannot be performed, and some liquid classes can be difficult to handle.

Assay miniaturization and low-volume liquid handling should also be considered. Assay miniaturization has been a real driving force in the evolution of liquid handling systems. Reducing the volumes of samples and reagents required provides cost and time-saving benefits for both the research and drug discovery industries.

This reduction has meant an increase in assay range and size and as a result, you can obtain more information per screen. For example, SPT Labtech’s dragonfly® discovery system can dispense non-contact volumes of 200 nL to 4 mL of any liquid class from positive displacement disposable tips into 1536, 384 and 96-well plates, enabling complex gradients, randomized dispensing patterns and dilutions to be performed.

Which is the best option for your lab?

*Scroll to view more information

Air displacement

Positive displacement

Acoustic technology

Typical volume range

2μL to 1000μL. Many manufacturers claim as low as 0.5μL but this requires very careful setup.

25nL to 10μL in current automated platforms. Manual positive displacement pipettes go to higher volumes up to about 1000μL typically.

2.5nL to 5μL

Good for

Aqueous samples, but more challenging, volatile, or viscous samples may need careful setup or may not be suitable.

All types of samples work well and with little or no need to optimize a system for each liquid type

Robust fast non-contact transfer of samples at very low volumes to microlitres

Benefits

Simple robust mechanism. Air cushion separates samples from mechanical parts and options such as filter tips minimize cross-contamination risks

Assured accurate and repeatable pipetting and zero cross-contamination risk if disposable tips are used

Has become a go-to method for μL and nL sample transfer across a variety of liquid types. Transfer can be verified.

Limitations

Not good for highly viscous, volatile or samples containing particulates. Less accurate at low volumes.

Consumables can be more expensive and fewer automated platforms feature this technology.

Gets slower with larger volumes due to the drop-by-drop approach and existing volume of liquid in destination plate can be a problem when inverted. Also a very expensive technology.

SampleTransfer

Yes

Yes

Yes

Mixing

Yes

Yes

No

Bulk dispensing

Possible but limited and may require use of a less accurate multi-dispense mode and may increase risk of cross-contamination. Multiple re-fills of tip often needed

Possible but limited and may require use of a less accurate multi-dispense mode and may increase risk of cross contamination. Multiple re-fills of tip often needed.

Limited to low-volume reagent dispensing and not really what itis designed for.

4. How much do automated pipettors cost?

Market prices for liquid handling systems range from less than $10K, all the way up to $500K on a sliding scale price and functionality – from low-priced, off-the-shelf pipettors to expensive bespoke workflow solutions.

As with any purchase decision, a strong business case is therefore essential to get buy-in from senior decision-makers. You need to be clear about the upfront and service costs, while also highlighting the long-term cost savings to present the real return on your investment.

When considering the purchase of an automated liquid handling instrument, much will depend on what workflows you'd like to automate. But whether you're looking for a versatile solution to automate as many applications as possible or improve the precision of a particular liquid handling step, it's important not to compromise on quality.

Are consumables readily available?

Supplies of disposable tips are an issue across the industry. It's therefore essential that you make sure your tip supply is available with a short lead time and in the volumes that you will need in future. Non-contact fixed heads don’t include an ongoing consumable cost and can offer super-fast dispensing, with throughputs that cannot be matched by systems that change tips. However, they do require routine maintenance to ensure peak performance. On the other hand, disposable tips are a consumable cost to factor in but offer peace of mind with respect to dispense performance, zero system maintenance and the utmost confidence in assay results where any potential for cross-contamination needs to be ruled out.

Use this calculator to compare the cost and time of manual pipetting vs automated pipetting.

5. Key components of automated pipettors

Pipetting head

Pipetting heads that transfer the liquid are either multi-channel or single-channel.

Control interface

A control interface allows users to configure and monitor their experiments either via a linked PC or an inbuilt touchscreen computer.

Liquid handling core

The liquid handling pipetting core, either fixed or interchangeable, allows researchers pipette and dispense the liquid into plates with different numbers of wells.

Deck

The deck secures consumables, such as plates, tip boxes or other accessories, in pre-defined locations for automated operation.

Pipette tips

The liquid is held in the pipette tips, which are either permanent or polypropylene disposable tips used to avoid x-contamination. After use, the disposable tips go into the waste.

Automated pipettor demo video (apricot S series)

In this video, our Product Manager, Anne Hammerstein, provides an overview of the apricot S1 and S3 and demonstrates some of the key features of the automated pipettors.

6. How does automated pipetting improve your workflow?

There's more to automation than the obvious increase in speed, throughput, and standardized accuracy. When choosing an instruments, consider if you need to automate a single liquid handling step, or do you require full workflow automation? The range of different solutions is extremely broad, and these are fundamental questions you need to ask yourself at the outset.

Laboratories will generally automate the liquid handling workflows for the following main reasons.

- Increase throughput

- Miniaturize assays into formats not possible by hand

- Improve assay reproducibility

- Reduce the variability of results between scientists

- Save valuable time and costs

- Minimize reagent use

- Relieve the boredom from the repetitive nature of routine assay preparation

- Reduce the potential for staff repetitive strain injury

- Free up resources for other tasks

Whatever your objectives, it's worthwhile being very clear about what you need from an automated system first, as possible choices range from simple benchtop pipettors to work cells for full process automation.

Off-the-shelf benchtop pipettors are a great choice when there isn't a single fixed application. You might want to fill plates one day, do a serial dilution the next, and remove media from cells on another day. Most benchtop pipettors are semi-automated, meaning a degree of user intervention is required to move the plates around, process a stack of plate, move them to an incubator. But, overall, you can expect out-of-the-box automation with minimal user training. These solutions can be set up and running within the hour.

Highly bespoke work cells are at the other end of this spectrum. These are mostly used to process lots of plates for a single well-defined application and provide full walk-away capability. There is, of course, a large price tag attached to these kinds of bespoke systems, which can be justified if you require the level of automation and throughput offered by the instrument. Typically, labs will be looking at extensive validation periods of up to six months. They will often have dedicated users operating these work cells versus completely agnostic systems, which anyone could walk up to and use.

Automated pipetting reduces RSI risks

Researchers who carry out manual pipetting tasks are at risk of repetitive strain injury (RSI), specifically strain of wrists, arms, and shoulders. In fact, researchers who are pipetting for more than two hours a day are at a 60% risk of suffering hand and shoulder ailments. These types of injuries and awkward postures develop over time and occur when muscles and joints are stressed and there is restrictive blood flow.

Automation eliminates these issues associated with manual pipetting. The automation of liquid handling isn't about replacing humans with robots. It’s about relieving laboratory staff of tedious and error-prone manual tasks, so they can focus on science.

What's an automated pipettor really like to work with?

In this Q&A, we spoke with Anita Pearson, an Applications Development Scientist at SPT Labtech, about her experience working with the apricot S3 instrument, an automated high-performance 96 and 384 channel pipettor for either low or high-throughput use.

7. Key considerations when purchasing an automated pipettor

Knowing what you need to automate is your obvious first consideration. Do you need to increase the accuracy of your results, improve assay reproducibility, or miniaturize assays into formats not possible by hand? Perhaps you want to save costs, minimize reagent use and free up your scientists' valuable time by removing repetitive tasks that can lead to strain injuries.

All considerations:

Are you looking for a tool that will be used by dedicated and experienced automation operators or would a tool that anyone can use be a better fit?

Are you processing single plates that can be moved manually on and off the deck, or do you have hundreds of plates that might require a solution with a robotic arm or a stacker?

How much flexibility do you need in terms of configuration, e.g. can you use a fixed liquid handling core, i.e. a fixed volume range, or would you benefit from being able to exchange the liquid handling core or deck accessories, such as heaters, shakers, or vacuum manifolds?

How much support do you need from your vendor? If it breaks, will the vendor send an engineer, or do you have to box up the instrument and send it to a factory? Where is that factory? You want good uptime.

Many liquid handlers can sit on a small bench space of one third of a square meter. In other words, you won't need an entire room to house the instrument.

That said, zero cross-contamination is critical for many labs, and maintaining a greater degree of sterility will have space implications. Sterile workflows might require you to keep your samples in a tissue culture hood and use other equipment to keep out contaminants. These additional requirements could ultimately demand more space than you had planned or otherwise impact your researchers' day-to-day work by reducing the bench space available to them.

You may like this blog, which looks at how multi-purpose technologies are helping to tackle the laboratory space conundrum.

You will want to get the most automation, the most workflow benefits out of the budget that you have available.

8. The best automated pipettor by application

The applications you want to automate will have a large influence over which automated liquid handling system you choose.

Low-volume liquid handling technology delivers exceptional accuracy and speed even at the smallest volumes.

Automated assay development is typically a laborious manual process because designing multi-factor experiments and setting up complex plate layouts is laborious and error prone. Automation software can help you here by allowing you to design multifactorial experiments rapidly and with ease. Dispensing technology then lets you set up complex combination gradients and gives you the ability to dispense from multiple channels.

When evaluating an automating pipetting system, you'll want to calculate how quickly you can make cost savings by considering factors such as how many samples you process per week or how often you use a particular workflow. But perhaps your purchase of an automated system is warranted by the necessary improvement in accuracy that it will provide. Whatever your goals, it's important not to forget the overall return on your investment. What other strategic development or research work might you accomplish by freeing up highly skilled staff and scaling your current processes?

Before you purchase an automated pipetting instrument, you need to know the range, variance, and accuracy of the pipetting and dispensing technology across a sample of representative liquids matching your application. But you'll also want to understand the flexibility of the products – how well might it accommodate the evolving needs of your lab. To that end, you should discuss any potential changes or future work that you might have planned with your vendor, so they can walk you through the available options and possible future upgrades.

A Buyer’s Guide:

Making the move to automated liquid handling

In this guide, we discuss the things you should consider as part of your business case when purchasing automated liquid handling equipment; and look at workflows that benefit from automation, so you can make an informed decision about how to proceed and how it can best work for you.

9. Ease of use and maintenance of automated pipetting solutions

Contrary to what you might have thought, you don't necessarily need experienced or dedicated in-house automation technicians to manage and maintain an automation pipettor. Vendors who provide support can set up applications for any member of your staff to then operate. In fact, once your protocols have been set up, it can take just a couple of hours to train up new users.

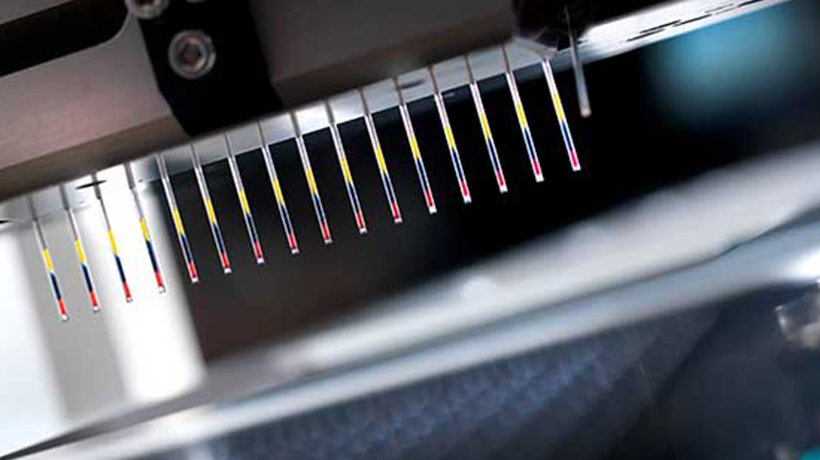

When you first purchase an automated liquid handling system, an engineer provided by the vendor can help you create a customized plan to demo the product and run spotting experiments with color dyes, so you can easily visualize the features and see how the product works.

Before purchasing a new liquid handling instrument, make sure you find out from the vendor what happens if the instrument breaks. Will the vendor send out an engineer to your site or would you have to halt operations and ship the equipment to the manufacturer yourself? What does the warranty cover?

Automation will of course make your day-to-day life easier.

However, it’s important to recognize that the instrument will need some level of maintenance, and you will need to carry out regular QC calibration checks. These are required to ensure the accuracy and precision of all liquid handlers, especially those containing valves. It’s a good idea to ask the lab service provider at the time of sales how much maintenance is required.

10. Get expert advice on automating your lab's workflows

If you find you have specific questions about a workflow you're considering automating at your laboratory, do reach out to us for more tailored advice.

At SPT Labtech, our expert teams create state-of-the-art solutions you can trust by working closely with scientists and researchers at our customers' laboratories. Take a look at our liquid handling portfolio, book a demo or get in touch – we'd love to hear from you!