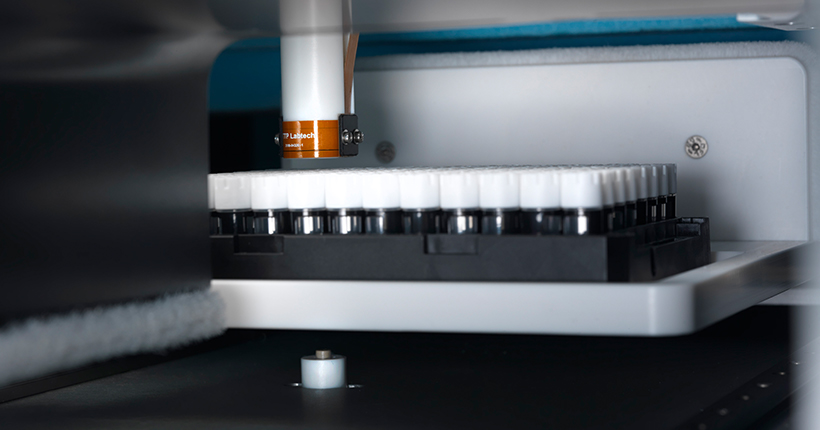

Automation improves how biobanks store and process samples. Automation systems offer high-density storage capacity and 2D-barcoded tubes for registering, tracking, accessing, and selecting samples – all of which improve the speed and organization of biobanking workflows. Automating some or all of these steps can significantly minimize the costs associated with wasted employee time manually searching for samples!

Current and future storage capacity requirements will determine whether automated solutions represent a viable alternative to manual freezers. Barriers to automation include the significant costs associated with the initial equipment purchase. Initial investment expenses for automation can be five to ten times more than manual operations. The ten-year running costs for fully serviced automated systems are estimated to be between €500,000 to €5 million.

When weighing up the advantages and disadvantages of automation, there are key factors to consider. Labor costs, energy costs, and space considerations are easily measured based on current usage and predicting future needs. Other “softer” factors, such as sample security and integrity, are more difficult to quantify yet are extremely important for the success of the biobank. Advances in automated sample storage and processing have focused on improving these qualitative requirements to make sure biobanks provide researchers with the highest quality samples.

.jpg?length=320&name=Twist%20x%20SPT%20Labtech%20Press%20Release%20(1200%20x%20800%20px).jpg)