- Applications

-

Products

-

Liquid Handling

- firefly Accelerate genomic research with innovative all-in-one, compact liquid handling

- mosquito Nanolitre liquid handling technology performs ‘traditional’ tasks at a fraction of the volume, and higher speeds

- dragonfly Delivers accurate and repeatable nanolitre to milliliter dispensing

- apricot Automated liquid handling instrumentation for convenient general use across your entire team

- Sample Preparation

-

Sample Management

- comPOUND A scalable, reliable, and secure compound management solution

- BioMicroLab Easy-to-use sample management automation instruments

- arktic Robust biospecimen storage and management down to -80°C

- lab2lab Novel sample and data transfer network system

- comPACT Reliable and efficient -20°C storage and retrieval has never been more accessible

-

Liquid Handling

-

About

- Company With a focus on liquid handling, sample preparation and sample management, our expert teams create state-of-the-art solutions that scientists and researchers can trust Culture We have one overarching mission: to work together to accelerate life science research. Through our innovative solutions and state-of-the-art tools, we believe we can make a real difference to human health Partners Collaboration is key in our mission to make a real difference to human health. Partnering with application leaders globally, we co-create to solve new challenges across the life sciences. Innovation From the initial prototype through to manufacturing, installation and beyond, we bring a problem-solving mindset and technical expertise to drive innovation

-

Executive Leadership

Through strategic guidance, visionary thinking, and a relentless pursuit of excellence, our senior executives steer SPT Labtech towards achieving its mission of making a real difference to human health through solving advanced laboratory challenges.

Learn more

Through strategic guidance, visionary thinking, and a relentless pursuit of excellence, our senior executives steer SPT Labtech towards achieving its mission of making a real difference to human health through solving advanced laboratory challenges.

Learn more

-

View all

Board of Directors

Board of Directors

Our Board of Directors are committed to driving the long-term success and sustainability of SPT Labtech, providing expert guidance and oversight to execute the company’s ambitious commercial strategy.

Learn more

Our Board of Directors are committed to driving the long-term success and sustainability of SPT Labtech, providing expert guidance and oversight to execute the company’s ambitious commercial strategy.

Learn more

-

Knowledge Base

- Resources Our wide range of insightful resources include videos, whitepapers, eBooks, application notes and more Events & Webinars Meet the SPT team at events all over the globe and virtually via our webinars Podcast We chat with innovators and leaders from across the community to gain their unique insights. News Latest news from SPT Labtech globally Blog Our latest blog posts feature trends in research, innovative techniques and new technology

-

25 February, 2026

SPT Labtech to collaborate with Illumina to develop automated platform supporting genomics in decentralized healthcare settings

Continue reading

SPT Labtech to collaborate with Illumina to develop automated platform supporting genomics in decentralized healthcare settings

Continue reading

-

09 February, 2026

SPT Labtech and BellBrook Labs Introduce High-Throughput Screening Platform for Cancer Research

Continue reading

SPT Labtech and BellBrook Labs Introduce High-Throughput Screening Platform for Cancer Research

Continue reading

-

14 January, 2026

.jpg?length=320&name=Twist%20x%20SPT%20Labtech%20Press%20Release%20(1200%20x%20800%20px).jpg) SPT Labtech enables automated Twist Bioscience NGS library preparation workflows on firefly platform

Continue reading

SPT Labtech enables automated Twist Bioscience NGS library preparation workflows on firefly platform

Continue reading

10

- Careers

- Home

- Products

- BioMicroLab

- BioMicroLab XL9

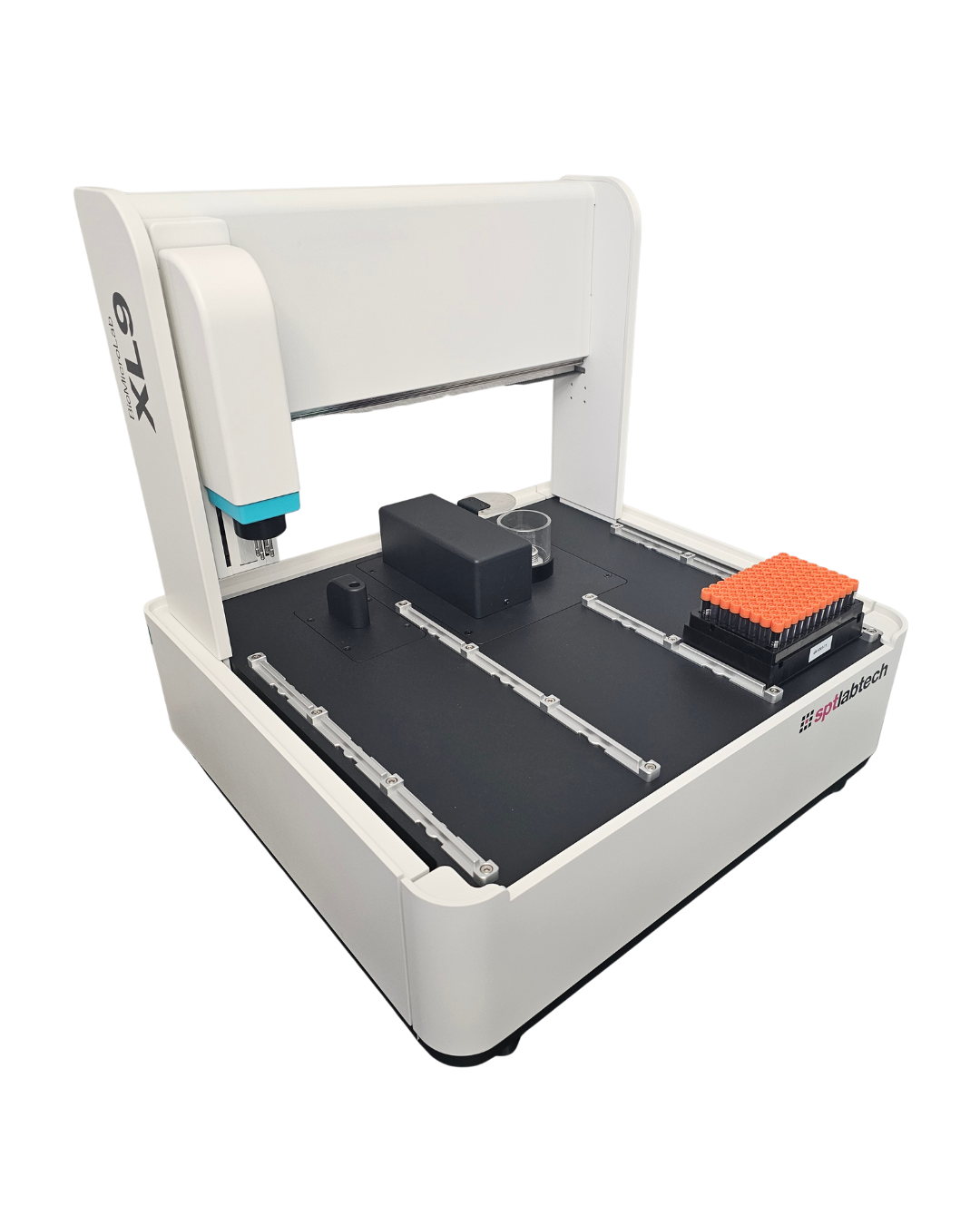

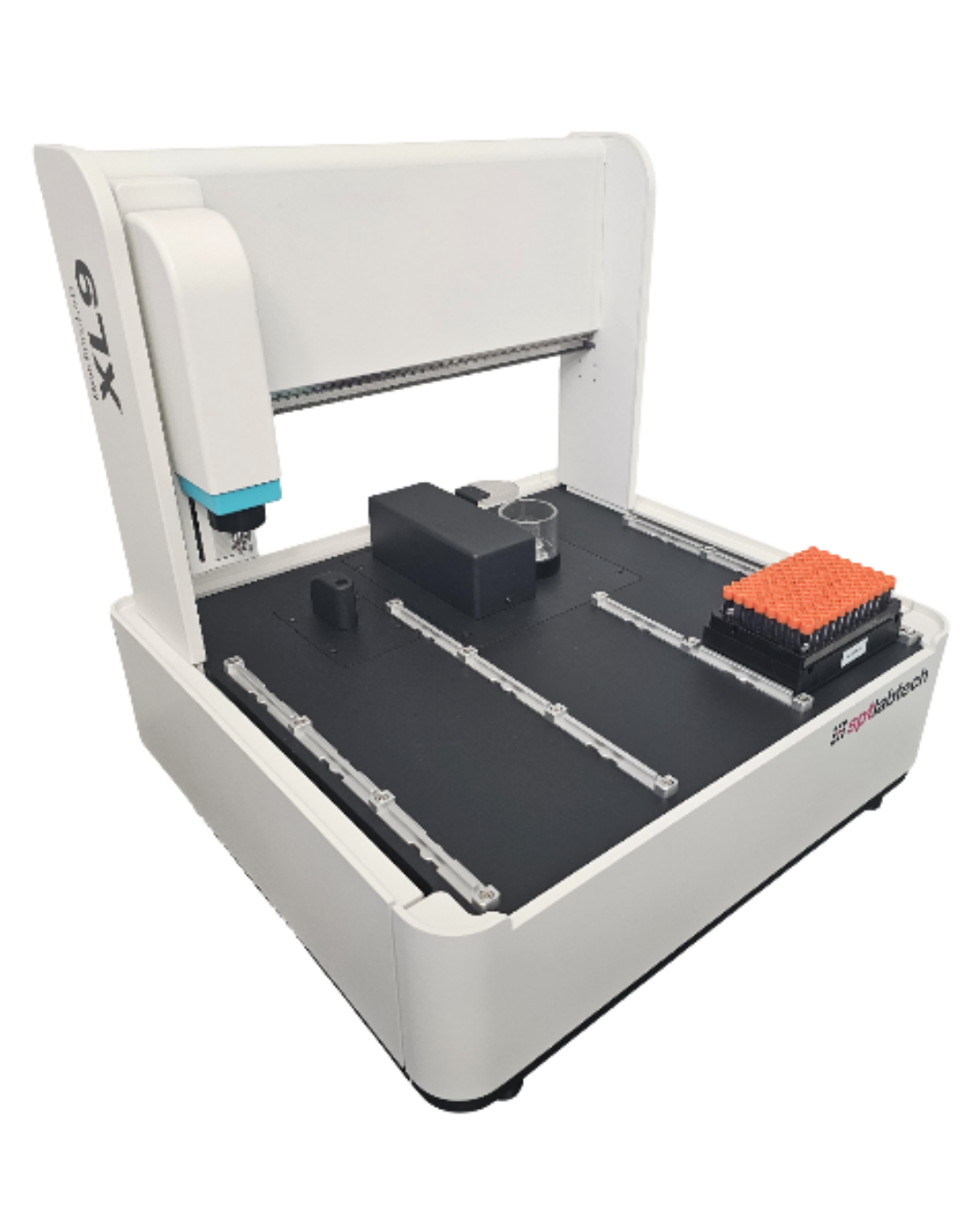

BioMicroLab XL9

Modular and flexible instrumentation to automate critical labelling, sample tracking, and volume detection workflows.

Easily configurable automated tube handler

The BioMicroLab XL9 tube handler for 96-format microtubes is easily configurable with labeling, sample tracking, and volume detection capabilities. With a 9 rack capacity, this instrument is particularly well suited for laboratories taking their first steps towards automation or with limited benchtop space.

Versatile capabilities enable streamlined workflows

The XL9 brings together scanning, decoding, volume detection, rearray and labeling functionality, giving researchers the flexibility to use it for individual tasks, or accomplish multiple tasks as part of a single workflow.

Small footprint maximizes available space

With a compact footprint of just 48 x 48 cm, the XL9 maximizes available benchtop space, enabling efficient laboratory layout - without compromising on capabilities.

High-throughput tube sorting increases productivity

The XL9 offers reliable, high speed capabilities for re-array, reformatting, and cherry picking and is able to sort over 1100 tubes per hour, providing unattended tube processing for work list based tube transfer from source racks to target racks.

Efficient sample identification and tracking

The XL9 decodes up to 740 tubes per hour, and seamlessly integrates 2D data matrix barcode decoding with other automated tube handling operations. The intuitive software application captures and reports each tube’s 2D barcode, tube location, weight, and volume to LIMS systems.

Simplify label printing and application with integrated labeling module

The BioMicroLab LabelPro labeling module easily attaches to the XL9 and prints and applies high-resolution 1D & 2D barcodes as well as human readable text and symbols - reducing the burden of manual labeling tasks and eliminating bottlenecks.

Efficient collection of sample weight data

To verify volume upon receipt of samples, or before/after liquid transfer operations, the XL9 integrates a precision automated balance to automate the collection of sample weight data.

Benchtop and high performance tube handling

The XL9 & XL20 Series Tube Handlers streamline volume detection, sample identification/verification, and labeling tasks to eliminate bottlenecks and transform tube handling workflows.

- Software

- Compatible labware

- Cold room compatibility

- Enclosures

- Label printing and application

- Sample identification and tracking

- Feature checklist

User-friendly

User-friendly Windows based software is included with all XL Series instruments to manage sample processing modes and robotic operations. BioMicroLab offers software developer toolkits for your instrument and workflow integration projects.

XL Work List Manager Software

Included with all XL Series instruments, the XL Work List Manager Software offers user-friendly management of vial pick and place operations. It provides multiple tube processing modes for common tube handling applications to meet varied workflow needs and allows researchers flexible control to increase your throughput. Output files can be easily configured to meet LIMS system requirements. Easily managed by multiple users, our full featured tube processing software provides walk away operation to meet throughput requirements even for demanding environments with advanced system error handling options. Software features include:

- User-friendly point-and-click Graphical User Interface

- Data collection and worklist based processing modes

- Functionality carefully guides the user through the tube rack loading and unloading processe

- Interactive interface provides feedback while processing tubes

- Dynamically processes extended work lists handling more racks than the XL Series platform capacity

- Integrates with hand-held barcode scanners for rack identification

- LIMS integration ready output files in .csv file format

- Tracks and logs all system activity

- Provides robust error-handling options for unattended tube processing

- SDK and ActiveX toolkits available

The XL9 is compatible with 96 well ANSI/SLAS microtubes (0.3 mL to 1.4 mL) from major labware manufacturers including:

-

Acoustic tubes

-

Altemis

-

Azenta (FluidX)

-

CryoKing

-

Greiner

-

LVL

-

Micronic

-

Thermo Matrix

-

And more, please inquire

When operator safety is a concern, the XL9 can be enclosed so that the instrument automatically shuts off when the door is opened. Clear, acrylic walls allow maximum light and visibility into the instrument to support comfortable user conditions. HEPA filtration for enclosures is now available.

Prints and applies high-resolution 1D & 2D barcodes as well as human readable text and symbols. User-friendly software allows operators to generate unique or identical labels using a variety of label materials and sizes.

The XL9 seamlessly integrates 2D data matrix barcode decoding with other tube handling operations, decoding up to 740 tubes per hour. BioMicroLab’s software captures and reports each tube’s 2D barcode, tube location, weight, volume and more to LIMS systems.

- Automates collection of tube 2D barcode, weight, and volume,

- Decodes 2D barcode with integrated camera

- Weighs sample with 0.1mg 4-place Balance (with Automated Balance option)

- Print and apply labels (with labeling option)

- Enclosure available for operator safety!

- Small 18” x 21” footprint

- Compatible with 96-well ANSI/SLAS standard tube racks

- Includes LIMS compatible BioMicroLab XL Series Work List Software

Technical Specification

Scroll to view more information

| Dimensions (W x D x H) | XL9: 480 x 480 x 475 mm XL9 with Labeling: 480 x 730 x 475 mm* |

Electrical | 100-240VAC ~ 50/60Hz |

| Weight | XL9: 22.6 kg (~50 lbs) XL9 with Labeling: 32.9 kg (~72.5 lbs) |

Operating Environment | XL9: 10°C to 40°C, 10-90% RH XL9 for Cold Rooms: -10°C* to 40°C, 10-90% RH *model dependant |

| System Requirements | Operating System: Operating System: Windows 11, 10; 8GB RAM Recommended USB Ports: Two |

Throughput (Operational Mode - Tubes/Hour) | Re-array only: over 1100 Re-array and 2D Decode: 740 Re-array, 2D Decode and Weigh: ~380 Re-array and Weigh: ~420 Re-array and Label: 220 |