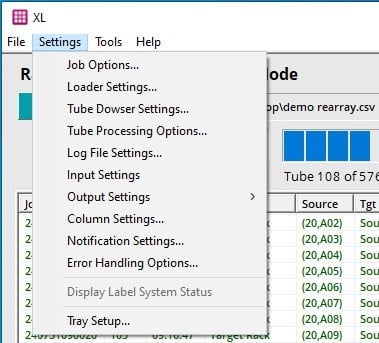

Software functions - Work List Processor Settings Menu

This menu allows you to set the various parameters of the XL20B software. Most parameters are set up once at the initial XL20B installation and retained by the XL20B software (in the Windows Registry, which is user specific).

Job Options

- This allows you to select the mode of operation for the type of tube handling job.

- If the XL20B is repeatedly used for the same type of job, this setting does not change

Loader Settings

- Use this to set up the COM port, camera, and scale settings between the XL20B and the host computer. Also use this to adjust the settling time of the optional analytical balance.

- If the XL20B is repeatedly used for the same type of job, these settings do not change.

Log file, Input file settings, and Output file settings

- Set up the directory location of the Log file and Output files.

- Select the data fields and content for the output file and input file.

- If the XL20B is repeatedly used for the same type of job, these settings do not change.

Error Handling Options

- Use this to select the error handling response by the XL20B to pick, place, and barcode error conditions.

- If the XL20B is repeatedly used for the same type of job, these settings do not change.

Job Options

The Work List Job Options form allows you to set the mode of operation.

Standard (Random) Processing Mode

- This is the recommended mode of operation for worklist based tube sorting.

- It allows loading tube racks onto the XL20B deck in a random manner - all racks placed on the deck will be processed, regardless of worklist sequence.

- This allows the fastest loading of tube racks (load all racks and start processing).

- It allows for dynamically processed jobs. For work lists with more racks than deck positions, the XL Work List Manager Software will process all tube positions available on the deck before stopping to be reloaded with more tube racks.

Sequential Processing Mode

- This does not allow for dynamically processed work lists. Work lists will stop processing if a rack is not loaded on the deck. Sequential mode may be more suitable for some processes as it follows a strict order.

Tare / Gross Weighing Mode

- No Work list is used in this mode of operation.

- This mode is used to quickly obtain tare weight of the tube.

- Tube racks are loaded and the process is started.

- After a tare weight is obtained, the tube may be filled with a sample and re-weighed to obtain the tube’s gross weight. The sample weight is determined from tare and gross weight data files.

- Weighing Mode generates input/output files to compare weight readings and determine the 'tare' weight of empty tubes, whereas Data Collection mode enables weighing and tube barcode reading

Data Collection Mode

- No Work list is used in this mode of operation.

- This mode is used to weigh tubes, to read their 2D barcodes or to weigh and read tube

barcodes. - Tube racks are loaded and the process is started.

- You can select whether to process racks by row or by colum.

Loader settings

The Loader Option selection allows selecting or deselecting XL20B instrument and balance

options.

Com Port settings

- Loader Com port: This is the serial port used by the host PC to communicate with the XL20B.

- Scale Com port: This is the serial port used by the host PC to communicate with the analytical balance option on the XL20B. If a USB to Serial converter cable is used, the COM port may display as a number greater than the usual COM1 or COM2.

Scale settings

- The 'Tare every number of steps' causes the XL20B to tare analytical balance (empty) for

every “n”th tube processed. Typical values are every 10, 24 or 96 tubes. - The 'Time to wait' settings set the settling delays for the balance.

- Recommended settings: 8000ms before tare, 3000ms after tare, and 5000ms before

weighing tube. - In environments where there are unstable conditions (external vibration or noise) these

values may need to be increased

- Recommended settings: 8000ms before tare, 3000ms after tare, and 5000ms before

Labware settings

- 'Display all labware' lists all configured labware types in the 'Labware Name' dropdown, to

select the labware in current use. - For convenience, you can identify your frequently used labware types with the 'Favorite

Labware' function.

Then when using XL20B, select the 'Display Favourite Labware' option, to only show those

labware types relevant to your lab.

- The 'Number of Trays' should be set to 20, for an XL20B.

Log file settings

Log files record mechanical errors.

- The default log file name is: XLLDR.LOG.

- You can select the folder used for the Log File.

The log image settings allow you to select if the images of the 2D bar code bitmap are saved in

addition to log file data.

- The “Save captured image only if the system fails to obtain barcode from the image" is the

recommended setting. This allows viewing the bitmap 2D image (by clicking on work list step in the Log File Viewer to check barcode decoding error issue.)

The log file can be viewed by selecting the File Menu, then View Log.

Input file settings

The Input File Settings form allows you to pre-define the input file [worklist] parameters to meet

the requirements of the XL20B file format in a way which works with your worklist file format e.g.

as used in your LIMS system.

Input File Settings Options:

- Pre-define the type file to be imported: .csv, .txt, or user defined

- Ignore rows and/or ignore rows that start with a user defined character

- Delimiters: Define delimiters used in your files. CSV is default, but other formats could be used.

- Order columns for input file preferences: you can order the fields to suit your LIMS system.

Work list format

The default work list file format is a comma delimited text file.

| Source | Source | Target | Target | |

| Rack Bar Code ID | Tube Location | Tube 2D ID | Rack Bar Code ID | Tube Location |

| 250001 | A03 | 0011379113 | 300000 | A01 |

In the work list example below, the system is picking a single tube from four different source racks and placing the tubes into one target rack (rack ID# 300000).

| Source | Target |

| 250001, A03, 0011379113, | 300000, A01 |

| 250002, H08, 0011557396, | 300000, A02 |

| 250003, F04, 0011556052, | 300000, A03 |

| 250004, E12, 0008286060, | 300000, A04 |

NOTE: Leading Zeroes in the 2D ID code

Some applications (i.e. Excel) may truncate the leading zeroes of the 2D ID code. To avoid this, use Excel's format feature to format the 2D ID code column as TEXT. If the XL20B software does not find the leading zeroes it may generate a barcode mismatch message; for example, 203072 is different than 0000203072

Worklist Processing Mode Output File Setup

The Output Folder Option selection allows you to set the directory where the output file is saved.

The output file contains the data obtained through work list processing.

Two files may be generated, the output file and the log file:

- The output file is saved for each completed target rack

- The output file name is: RackID#.CSV or can be user defined (for latest values for target rack)

- The log file name is: RackID#.LOG (for accumulated values for target rack)

The output file contains selectable fields, including:

- Tube position, 2D tube ID, tube weight, rack ID

Output File Format List

The XL20B software will save the output and log files to the directories specified in the Settings

Menu.

Output data files are based on target rack ID number and have different file name extensions based on processing mode or user defined values. These can be configured to be compatible with your LIMS system.

| Task | Mode | Notes (output file name) |

| Sort tubes | Work List Processing | Requires work list Job data saved in output file (Filename: RackID#.CSV – default) Note: this stores latest values (Filename: RackID#.LOG) Note: this stores accumulated values |

| Weigh tubes | Work List Processing | Requires work list Job data saved in output file (Filename: RackID#.CSV – default) Note: this stores latest values (Filename: RackID#.LOG) Note: this stores accumulated values |

| Read tube barcode | Work List Processing | Requires work list Job data saved in output file (Filename: RackID#.CSV – default) Note: this stores latest values (Filename: RackID#.LOG) Note: this stores accumulated values |

| Tare weight of empty tub | Tare / Gross Weight Mode | No work list is used Job data saved to output file (Filename: RackID#.TWT ) |

| Gross weight of filled tube | Tare / Gross Weight Mode | No work list is used Job data saved to output file (Filename: RackID#.GWT) |

| Weigh tubes | Data Collection | No work list is used Job data saved in output file (Filename: RackID#.CSV – default) Note: this stores latest values (Filename: RackID#.LOG) Note: this stores accumulated values |

| Task | Mode | Notes (output file name) |

| Read tube barcode | Data Collection | No work list is used Job data saved in output file (Filename: RackID#.CSV – default) Note: this stores latest values (Filename: RackID#.LOG) Note: this stores accumulated values |

| Task | Mode | Notes (output file name) |

| Tube movement log | All modes | Contains cumulative tube movement log (Filename: TUBELOG.LOG) |

| Error condition log | All modes | Contains error / exception data (Filename: LDRLOG.LOG) |

.png?width=300&height=157&name=spt%20logo%20png%20(1).png)